In the field of electrical appliance repair, the electric soldering iron is an indispensable tool. It is widely used in the repair of circuit boards, replacement of components, and the establishment of various electronic connections. This article will introduce in detail how to use an electric soldering iron in the process of electrical appliance repair, and provide some practical skills and precautions.

I. The Importance of Electric Soldering Iron in Electrical Appliance Repair

During long-term use of electrical equipment, component aging, damage, or poor connections may occur. In these cases, the electric soldering iron comes into play. With the soldering iron, repair technicians can easily disassemble and replace damaged components, or resolder loose connection points, thereby restoring the normal operation of the electrical equipment.

II. Preparation for Using Electric Soldering Iron

- Selecting a Suitable Electric Soldering Iron: Choose an electric soldering iron with moderate power and a suitable soldering iron tip shape according to the repair task requirements. Different soldering iron tips are suitable for different soldering scenarios. For example, a knife-shaped soldering iron tip is suitable for large-area soldering, while a pointed soldering iron tip is more suitable for precision soldering work.

- Preparing Soldering Materials: Prepare necessary soldering materials such as soldering wire and soldering flux. High-quality soldering wire and flux can improve soldering quality and reduce potential problems during the soldering process.

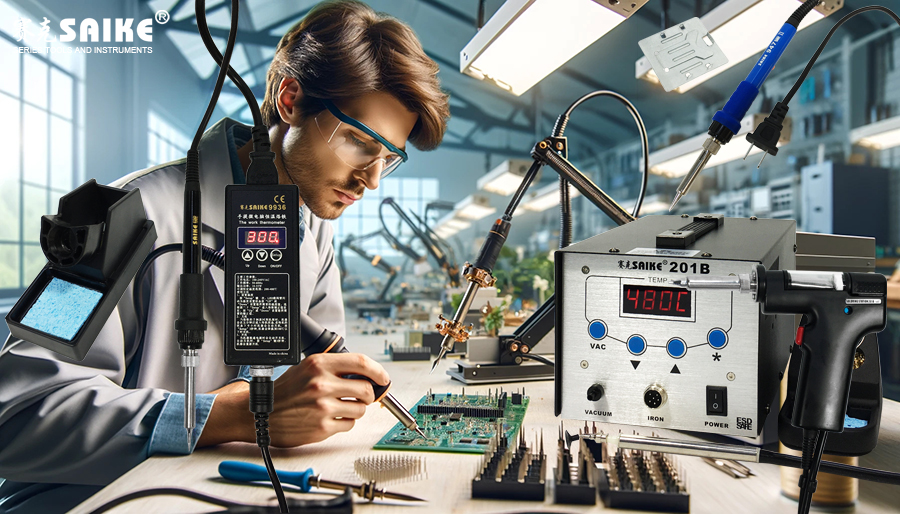

- Ensuring Safety: Check whether the power cord of the soldering iron is intact, ensure that the work area is clean and tidy, and keep it away from flammable items. At the same time, wear protective equipment such as heat-resistant gloves and goggles to prevent burns and eye damage caused by splashes.

III. Practical Skills of Electric Soldering Iron

- Preheating and Temperature Control: Turn on the soldering iron and preheat it to the appropriate temperature. Use a temperature controller or infrared thermometer to monitor the temperature of the soldering iron tip to ensure it is within a suitable soldering range.

- Cleaning the Soldering Iron Tip: Before soldering, use a wet sponge or special cleaner to clean the oxides and soldering slag on the soldering iron tip to maintain its good thermal conductivity.

- Soldering Operation: Place the soldering iron tip at the position that needs to be soldered. After the soldering iron tip is heated to an appropriate temperature, touch the soldering wire to the soldering iron tip and soldering point to melt and fill the connection. During the soldering process, a moderate amount of soldering flux can be used to enhance the fluidity of the soldering wire.

- Inspection After Soldering: After soldering is completed, carefully check whether the soldering joint is solid, smooth, and without false soldering. If necessary, tools such as a multimeter can be used for electrical performance testing.

IV. Precautions and Common Problem Handling

- Avoid Overheating: Overheating may damage components or deform the circuit board. Therefore, strictly control the heating time and temperature during the soldering process.

- Prevent False and Cold Soldering: False soldering and cold soldering are common soldering problems that can lead to poor electrical connections. To avoid these problems, ensure that the soldering iron tip and soldering wire fully contact the soldering point and maintain appropriate heating time.

- Handling Poor Soldering: If poor soldering is found, such as unstable soldering joints or false soldering, it should be handled in a timely manner. The soldering iron tip can be used to reheat the soldering joint, and an appropriate amount of soldering wire can be added for remediation.

V. Summary

In electrical appliance repair, the electric soldering iron is a very important tool. By mastering the correct usage methods and practical skills, we can effectively use the soldering iron to complete various repair tasks. At the same time, attention to safety and quality control is also essential. I hope this article can provide some useful guidance and help for everyone to use the soldering iron in the process of electrical appliance repair.