The electric soldering iron is a commonly used tool for electronic engineers and enthusiasts, playing a crucial role in soldering circuit boards and components. However, as a consumable item, the electric soldering iron has a limited service life. This article will delve into the service life of the soldering iron and effective ways to extend its lifespan, helping you better maintain and use this handy assistant.

I. The Service Life of Electric Soldering Iron

The service life of an electric soldering iron is influenced by various factors, including the quality of the soldering iron, frequency of use, and maintenance conditions. Generally, a high-quality electric soldering iron, when used and maintained correctly, will have a longer service life. But even the best soldering iron will experience performance degradation and tip wear after prolonged use.

II. Methods to Extend the Service Life of Electric Soldering Iron

- Choosing a Suitable Electric Soldering Iron

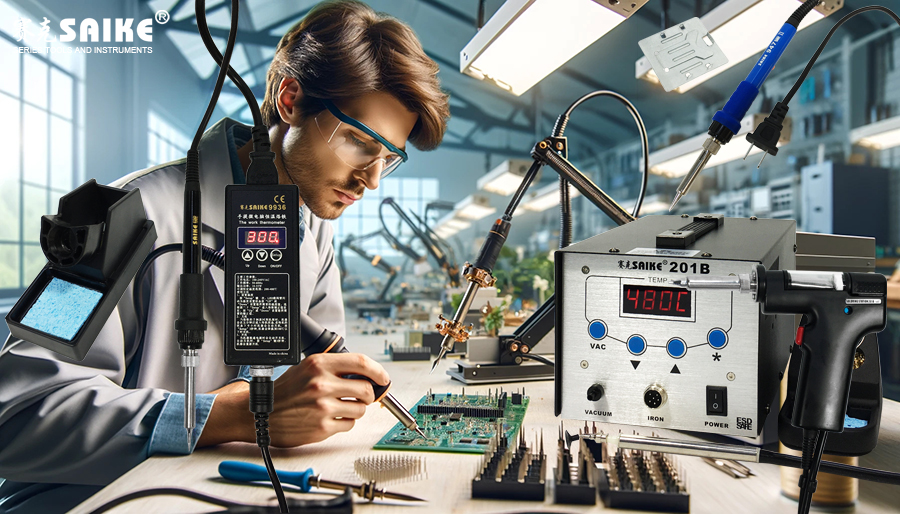

When purchasing an electric soldering iron, one should choose a high-quality, reliable brand. A high-quality soldering iron typically offers better durability and stability, enduring longer use.

- Proper Usage

When using the soldering iron, one should follow the correct operating procedures. Avoid excessive heating or improper use that could damage the soldering tip. Additionally, select the appropriate soldering tip and temperature setting according to the soldering task.

- Regular Cleaning and Maintenance

- Cleaning the soldering tip: During soldering, the tip can accumulate solder residue and oxides. After each use, clean the soldering tip with a specialized tip cleaner or fine sandpaper to maintain its good thermal conductivity.

- Replacing the soldering tip: After prolonged use, the soldering tip may wear or deform. Once performance degradation is noticed, promptly replace the soldering tip.

- Storage and Maintenance

- Avoid damp environments: Store the soldering iron in a dry, ventilated place to prevent rust or corrosion of the soldering tip due to dampness.

- Applying anti-oxidant: For soldering irons that won’t be used for an extended period, apply a layer of anti-oxidant to the soldering tip to prevent oxidation.

- Electrical Safety Precautions

When using the soldering iron, be mindful of electrical safety. Avoid using damaged power cords, and regularly inspect power sockets and cords for integrity.

III. Conclusion

Extending the service life of an electric soldering iron requires attention to selection, usage, and maintenance. By choosing a high-quality soldering iron, using it correctly, and maintaining it properly, we can effectively prolong its lifespan and improve soldering efficiency and quality. Additionally, safe use of the soldering iron is crucial for ensuring personal safety. Hopefully, this article provides helpful guidance for using and maintaining your soldering iron.