The electric soldering iron is an essential tool for electronic engineers and enthusiasts during soldering work. To maintain the good performance of the soldering iron, prolong its service life, and ensure soldering quality, proper cleaning and maintenance methods are crucial. This article will detail the cleaning and maintenance steps for electric soldering irons, helping you better maintain and use this tool.

I. Cleaning Methods for Electric Soldering Iron

- Cleaning the soldering tip: The soldering tip is the most critical and also the most vulnerable part of the soldering iron to dirt and oxidation. After use, the soldering tip may have residual solder, oxides, and other impurities. To clean the soldering tip, follow these steps:

-

- First, ensure that the soldering iron has completely cooled to avoid burns.

- Use a wet sponge or fine sandpaper to gently wipe the surface of the soldering tip, removing residual solder and oxides. Avoid using overly rough sandpaper to prevent damaging the soldering tip coating.

- If there are stubborn stains on the soldering tip, you can use special soldering tip cleaner. Spray the cleaner on the soldering tip and wipe it clean with a sponge or cloth.

- Cleaning the soldering iron shell: In addition to the soldering tip, the soldering iron’s shell also requires regular cleaning. Use a soft cloth or cotton swab dipped in a small amount of alcohol to gently wipe the soldering iron’s shell, removing dust and oil stains.

II. Maintenance Methods for Electric Soldering Iron

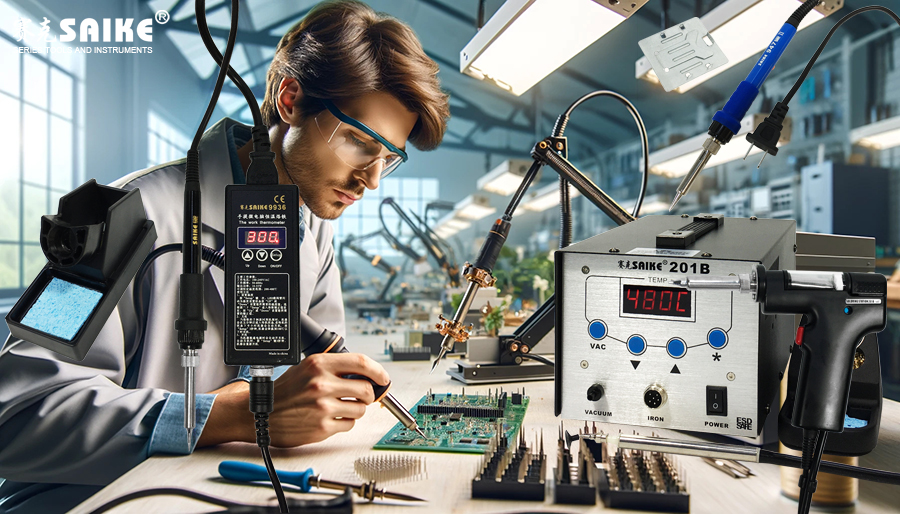

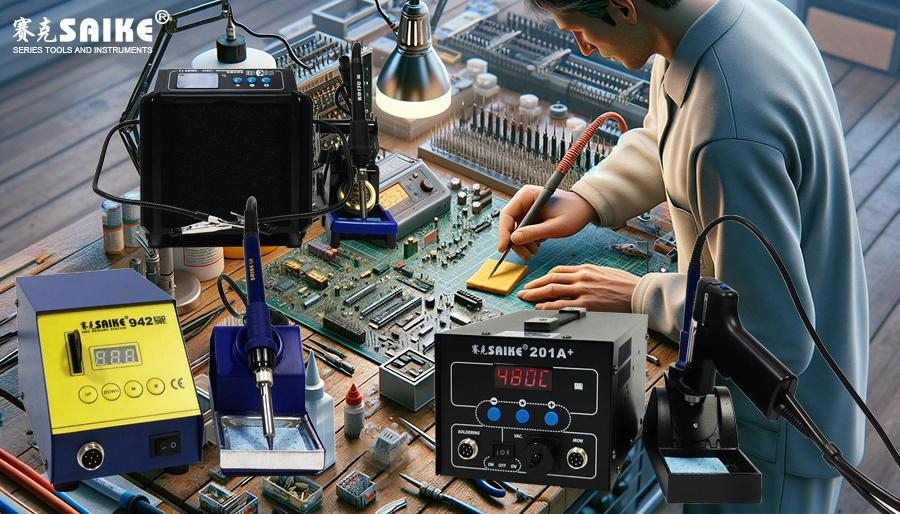

- Maintain moderate temperature of the soldering tip: When using an electric soldering iron, adjust the temperature according to soldering needs. Excessively high temperatures can accelerate the oxidation and wear of the soldering tip, while too low temperatures may result in insecure soldering. Therefore, choosing the right temperature is essential for soldering iron maintenance.

- Avoid direct contact between the soldering tip and metal surfaces: When not in use, the soldering tip should be placed on a soldering iron stand to prevent direct contact with metal surfaces. Direct contact with metal can cause the soldering tip to oxidize rapidly, shortening its lifespan.

- Regularly replace the soldering tip: Soldering tips are consumables and will wear and oxidize over time. To maintain soldering quality and extend the soldering iron’s lifespan, it is recommended to replace the soldering tip regularly. Follow the manufacturer’s instructions when replacing.

- Store in a dry environment: The soldering iron should be stored in a dry, ventilated environment to prevent water ingress or dampness. A humid environment can accelerate the oxidation and corrosion of the soldering tip.

- Use suitable solder and flux: Choosing the right solder and flux can reduce wear and oxidation of the soldering tip. It is recommended to use cored solder because the flux in the core can protect the soldering tip from contamination and provide good soldering results.

Summary

Proper cleaning and maintenance methods are crucial for extending the lifespan of the soldering iron and improving soldering quality. By regularly cleaning the soldering tip and shell, maintaining a moderate temperature, avoiding direct contact with metal, regularly replacing the soldering tip, and paying attention to storage conditions, you can better protect and use your soldering iron tool. I hope this article’s introduction can help you!