In the modern electronics manufacturing industry, precision welding of micro components is a crucial technique that ensures the high performance and reliability of complex electronic products such as smartphones, computers, and medical equipment. The welding process of micro components requires extremely high precision and control to cope with the continuous shrinkage of component sizes and the increasing complexity of designs. This article will delve into the key techniques, equipment selection, operational skills, and strategies for overcoming challenges in precision welding of micro components on a soldering station.

I. Key Techniques for Welding Micro Components

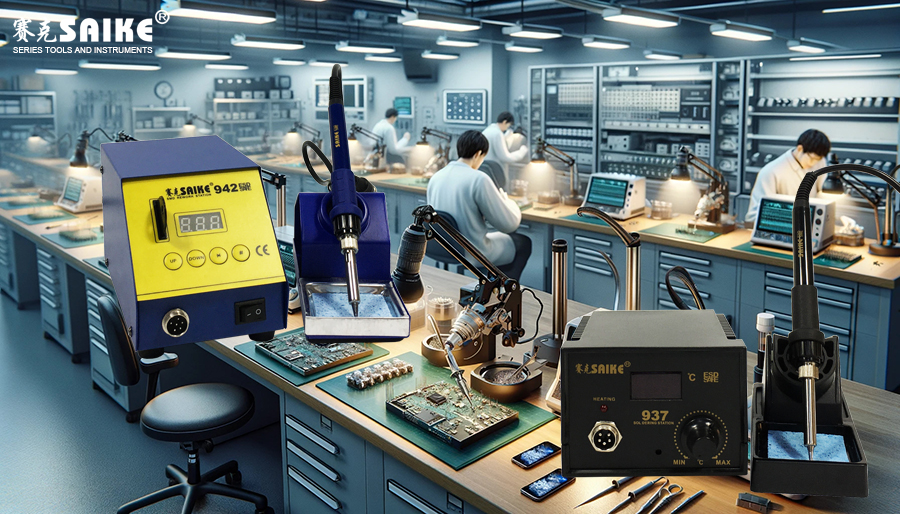

- Selection of Soldering Station and Soldering Iron

- Selection of Solder and Flux

- Optical Auxiliary Equipment

II. Welding Operation Skills

- Precise Solder Position Control

- Heat Management

- Refined Welding Techniques

III. Strategies for Overcoming Challenges

- Avoiding Electrostatic Damage

- Quality Control

- Training and Skill Improvement

IV. Conclusion

Precision welding of micro components on a soldering station requires a high level of technical expertise and precise operation. By selecting appropriate tools, adopting correct welding materials and techniques, and implementing strict quality control procedures, welding quality can be effectively improved, extending the service life of electronic products. As electronic devices move towards smaller and more complex designs, the importance of precision welding technology will further increase, and the requirements for operational skills will continue to rise.