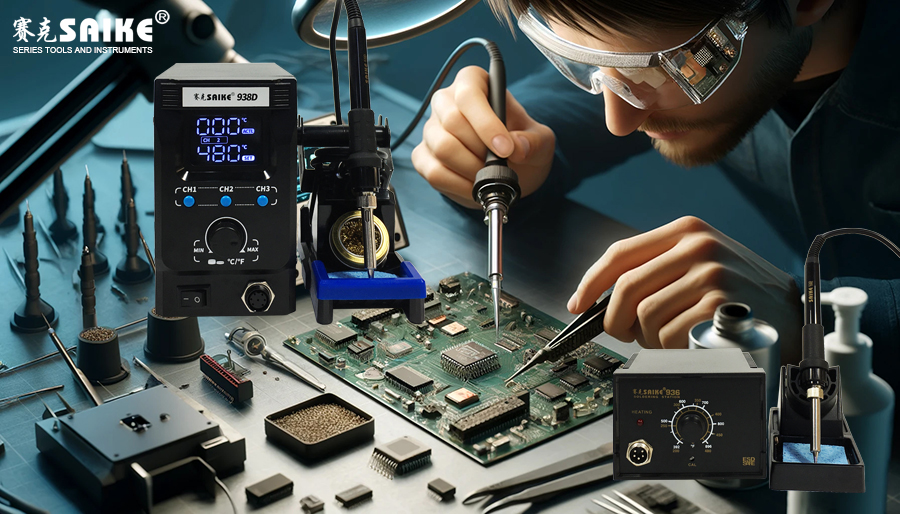

Surface-Mount Technology (SMT) plays a crucial role in modern electronics manufacturing, enabling automated machines to precisely and quickly place tiny components on circuit boards. While many SMT components are soldered during production using solder paste and reflow soldering processes, manual soldering of SMD components on a soldering station remains important in prototyping, small-batch production, or repair services. Here are some tips and suggestions for manually soldering surface mount devices.

I. Preparation

- Understand Component Characteristics

- Tool and Material Selection

- Clean the Soldering Area

II. Soldering Techniques

- Temperature Control

- Soldering Sequence

- Soldering Skills

III. Inspection and Cleanup

- Visual Inspection

- Cleaning

IV. Safety and Maintenance

- Soldering Iron Maintenance

- Personal Safety

V. Conclusion

Although soldering SMD components on a soldering station may be more challenging than traditional through-hole components, using the right tools, materials, and techniques can effectively accomplish these tasks, ensuring high-quality soldering results. Experience accumulation and meticulous operation are key to improving soldering quality, while also focusing on safety and health protections.